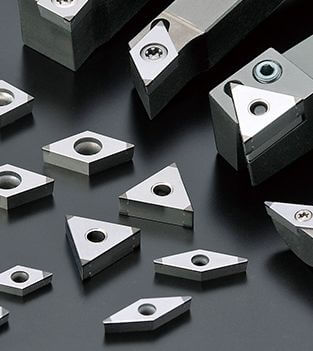

We produce diamond and

CBN tools

We are a family company with tradition since 1933

products and services

An overview of the products and services we offer.

Linkedin news

Follow the newest information about our company on LinkedIn.

Urdiamant s.r.o.

2120 followers

School’s back! 🛠️

The school year has started 📚 and so did our continued partnership with our local vocational school.

We were excited to recently host an excursion visit from a group of students.

We had a great time showing them our facilities 🏭 and discussing the upcoming semestral project 💡 we’ll be starting together!

We look forward to a successful and productive semester with this talented group! 🚀

Customer visits welcome

Come visit us in Šumperk!

At Urdiamant💎, we believe in the power of personal connection.🤝

That’s why we’re inviting our customers to visit us for a one-on-one technical consultation.

Come see our capabilities firsthand and let’s discuss how we can help you achieve your goals.🎯

Looking forward to welcoming you! 🙌😊

🔪 Need to sharpen the blades in your CNC cutter?

Is your CNC cutting machine struggling with dull blades or inconsistent performance in mass production? We have the solution! ⚙️✨

✅ Keep your operations running smoothly and efficiently with consistently sharp blades!

📞 Contact us to find the right tool for your needs.

Who we are

Overview of the most important information about our organization that give you the idea of who we are and how we do business.

OUR FOCUS

Production of Diamond and CBN (Cubic Boron Nitride) tools; over 20 000+ products & services are in our portfolio.

GEOGRAPHICAL SCOPE

innovation

Innovation is our daily bread. Every year we invest >3% of NS into R&D to provide our customers with the best possible solutions.

COOPERATION WITH RESEARCH INSTITUTES

We develop products & services in cooperation with prime technical universities (VŠB OSTRAVA and VUT BRNO).

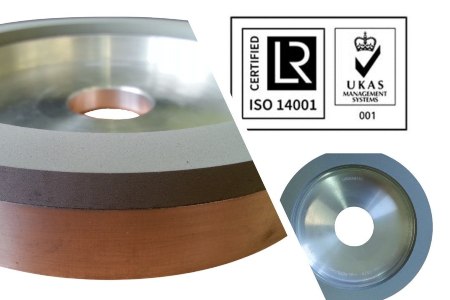

CONSTANT QUALITY. ENVIRONMENTAL SAFETY

Both of these factors play an integral part in our way of doing business. See our ISO certification here.

CUSTOMER-CENTERED PRODUCTION

We provide standardized, as well as tailor-made products. OEAM and private labels are also available options upon request.

QUICK LEAD TIMES

Majority of our standard products can be delivered in 4 weeks.

FLEXIBLE LOGISTICS OPTIONS

To minimize the lead time of our products, we offer the options of call-off stock, or consignment stock to our valued customers.

Video about our work

Diamond tools. A form of art itself.

This video shows what our work is like and why we believe it to be a sort of an art form itself:

- Experience, skills and passion are crucial aspects in our line of work.

- Our work has layers to it. Only through a combination of multiple steps are we able to get to the final product.

- We approach every piece of our production with caution, carefully checking every little detail.

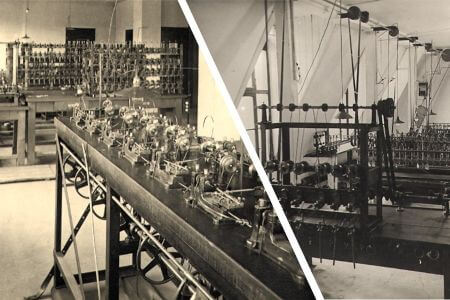

History of our company

Overview of important and interesting milestones in the history of our company.

1933

Beginning of production of diamond tools in the company Stellwag & registration of the Urdiamant™ trademark

1966

Urdiamant became part of a state-owned company Pramet, specialized in powder-metallurgy products and tools

1967

First synthetic diamonds produced in Šumperk

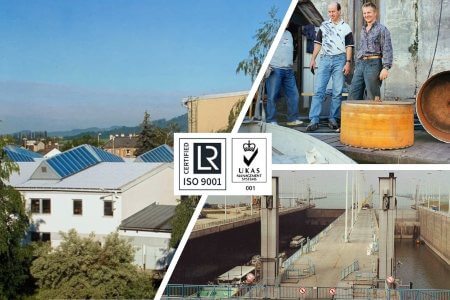

1995

We start producing non-coring bits with polycrystalline diamond cutters and a sintered matrix core

1998

Participation on the first international exhibition GrindTec (participated ever since) and moving to new premises

2000

Founding of an independent company Urdiamant, s.r.o.; first ISO 9001 certification; participation on the reconstruction of floodgates of the Gabčíkovo waterworks in Slovakia

2003

Co-founding of an endowment fund to support higher education in Šumperk through cooperation with VSB – the Technical university of Ostrava

2007

Participation on reconstruction of the Dlouhé stráně pumped-storage hydro power station

2008 & 2009

First hybrid bonds in our product portfolio & registration of trademarks: Flute – Speed ®, Insert – Speed ®, Ultra Tec ®, Dome Drill ®

2015

First vitrified bonds in our product portfolio; first ISO 14 001 certification

2016

Successful test of grinding wheels for production of indexable inserts using electro-erosive dressing system “PowerGrind” by company Agathon (CH)

2018

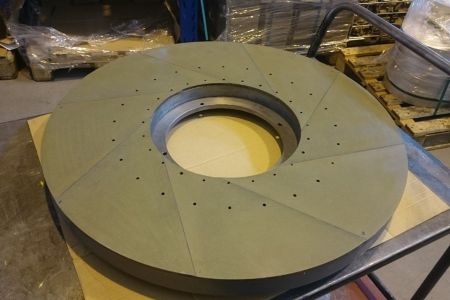

First grinding wheels for top & bottom flat honing and fine grinding on machines like Stähli, Peter Wolters, Melchiorre, etc.

2019

Registration of a trademark Rock-Snake ® for wire-line coring bits for geological surveying

2020

Founding of a training facility for CNC machining together with Šumperk´s vocational school

Dolnostudénská 715/3, Šumperk 787 01, Czech Republic

VAT ID: CZ 258 58 653