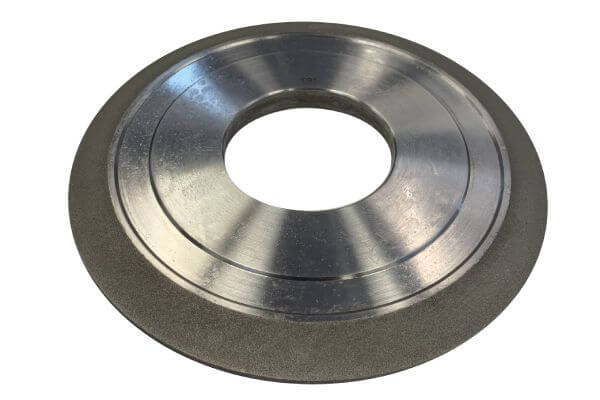

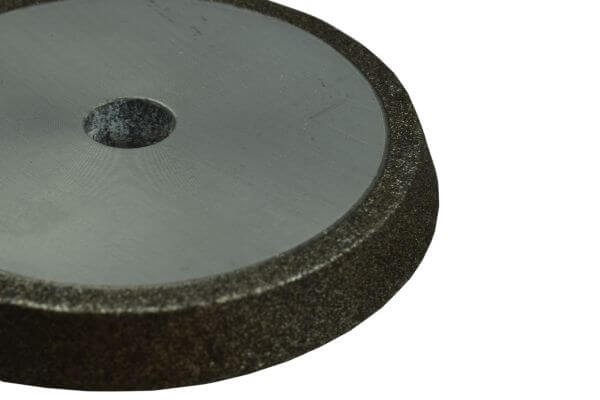

Electroplated diamond and CBN grinding wheels

Characteristics and usage

Contrary to the sintered grinding wheels, electroplated grinding wheels can have core bodies in a huge variety of shapes. Therefore, electroplated wheels are an ideal fit for grinding of special profiles in workpieces.

Another advantage is that higher speed of grinding can be employed at a minimal production of heat.

Last, but not least, electroplated grinding wheels can be stripped of the diamond / CBN layer and replated. This represent significant economical advantage.

Electroplated diamond / CBN grinding wheels are suitable in following applications:

- Production of small and complicated profiles

- Requirement of highly precise profile of the grinding wheel

- Inability to dress the wheel during grinding

- Longer total lifetime of the tool is required (incl. renovations)

Leaflet about electroplated tools

Ground materials by type of an abrasive

Diamond

- Technical ceramics

- Fiberglass

- Plastics

- Composite materials

- Stone, marble

- Glass

- Non-ferous metals

- Rubber

CBN

- High speed steel (HSS)

- Pressure steel

- Carbon steel

- Stainless steel

- Alloy steel

- Nickel superalloys

Available products and services

Diameter

max. 600 mm

Grit size

- Diamond: D25-D1181

- CBN: B35-B1181

Shape of a wheel

Upon individual consultancy. Contact us!

Renovation

We can renovate customers´ wheels on their own core bodies upon individual consultancy. Contact us!

See examples of our products

Dolnostudénská 715/3, Šumperk 787 01, Czech Republic

VAT ID: CZ 258 58 653