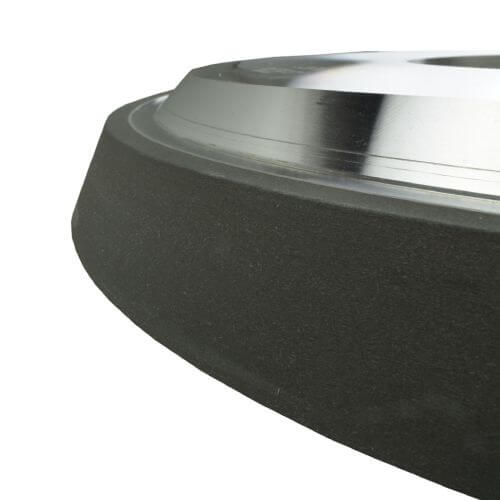

DIAMOND GRINDING WHEELS FOR TECHNICAL CERAMICS

Characteristics and usage

Technical ceramics is one of the hardest materials in the world. It is employed in production of products and parts that are used across almost all industries – from healthcare, through automotive and aerospace industries, to mechanical engineering, energy, production of consumer goods, weaponry, etc.

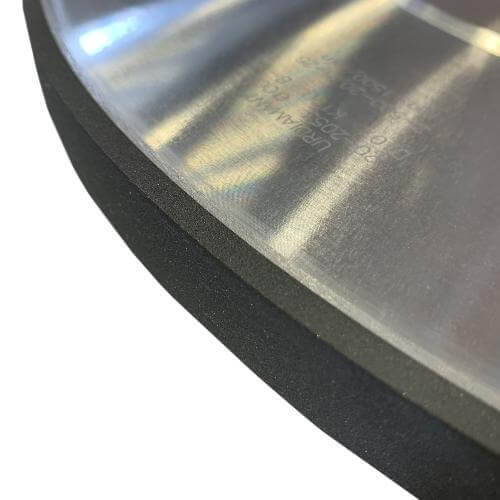

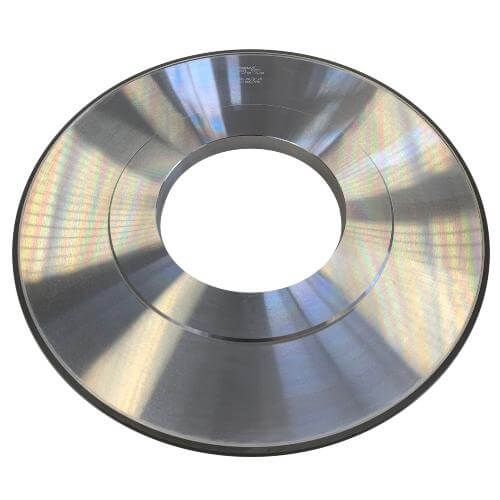

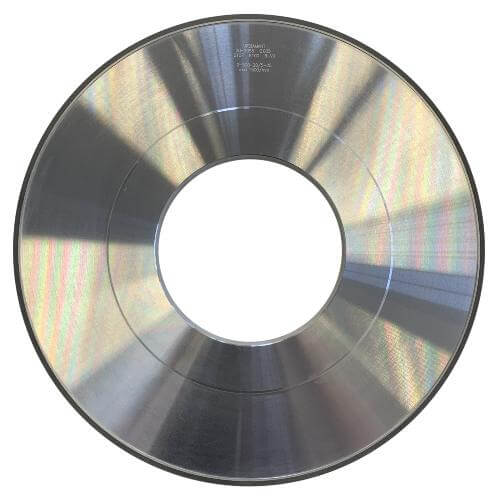

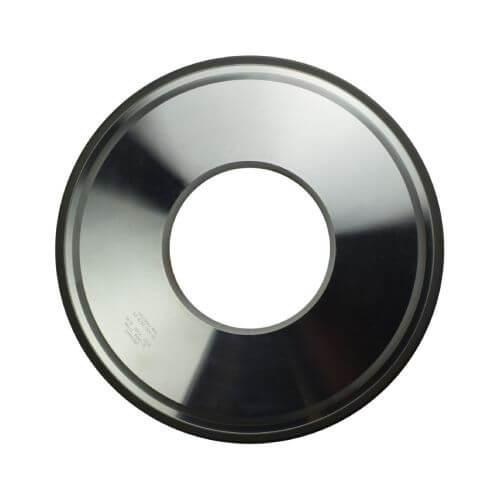

Precise machining of technical ceramics is extremely difficult due to its hardness. Grinding with use of diamond tools is one of the efficient methods how produce products from technical ceramics in high tolerances and various shapes. For these purposes we produce grinding wheels and other tools of all kinds, shapes and sizes.

We will gladly offer our consultancy and find the right solution for your grinding application.

Available products and services

Materials to be ground:

- Al2O3, SiSiC, Si3N4, Zr2O3

- Many other types of technical ceramics, cermets, etc.

FEPA types:

- We offer all kinds of wheels for various grinding applications – peripheral, cylindrical, surface, plunging, etc.

- 1A1, 14A1, 6A2, 3A1, etc.

We offer standard wheel types, but also customized tools. Contact us for personal consultancy.

Dimensions: depend on the FEPA type. Contact us for more information.

Bonds:

- Resinous, vitrified, metal

- We will recommend the right bond type after personal consultancy Contact us to arrange one!

Our wheels are usable with grinding machines such as:

Other types of tools for machining technical ceramics

(click on the links below for more information)

- Top and bottom flat honing and fine grinding wheels for grinding machines Stähli / Peter Wolters / Melchiorre, etc.

- 1A1 diamond grinding wheels of bigger diameters (>500 mm)

- Centerless diamond grinding wheels

- Drills for glass and ceramics

- Diamond saw blades with continuous rim

See examples of our products

Dolnostudénská 715/3, Šumperk 787 01, Czech Republic

VAT ID: CZ 258 58 653